FUJIFILM DRY PHOTO LAB DL450

Living with new technology

The DL450 is an extremely versatile printer. With the capability to have 4 rolls of paper loaded simultaneously, to dual-track two of those rolls to double the throughput and the ability to print duplex on cut-sheets, this looks like a small photo lab’s ideal tool.

Added to the list of cool features is minimal daily maintenance and no calibration. Ever!

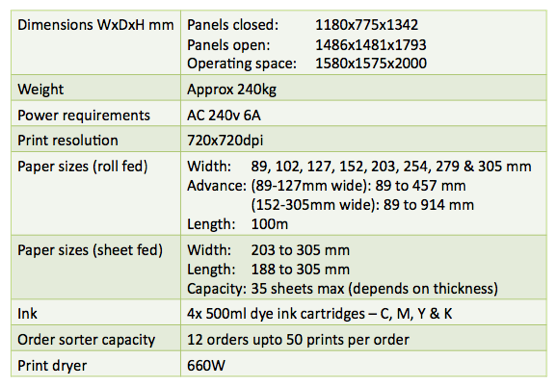

Basic specifications

Under the hood

Paper

Paper rolls are first loaded in to a large, moisture-resistant cassette which is very similar to the light-tight cassettes used by the Frontier wet labs. Cassettes can be swapped in and out of the printer as needed.

Access to the cassettes is easy via runner-mounted drawers. Paper auto-loads once the drawer is pushed fully home. As you would expect, if there are any paper errors, plenty of warning is visible on the main management MS screen.

Cut sheets, both simplex and duplex, are manually loaded into the auto-feeder at the front of the machine.

When printing duplex, the management software guides the user to insert the paper the correct way round for the second pass.

Paper storage is critical as inkjet paper is very sensitive to humidity and temperature, both high and low. All the time the paper is stored in its original sealed packaging between 15 & 30 Celsius it is fine. But, as soon as it is opened it has to be treated carefully. The DL450 cassettes are pretty well sealed against humidity when they are outside the printer. Once loaded there is a humidity/temperature control device for each cassette that ensures the paper stays in good condition.

That being said it is a good idea to ensure open packs of paper are not allowed to hang around too long.

Upper cassette drawer

Loaded cassette

Cut sheet auto-feeder

Ink

Being an inkjet-based printer, the DL450 needs ink. This comes in big 500ml cartridges. 4 of them, one each for cyan, magenta, yellow and black (CMYK).

The ink cartridges are found behind a small door on the front of the printer, about halfway down on the left. Opening the door reveals the four cartridges which are not only clearly marked which is which but they are also keyed to ensure it is not possible to insert the wrong colour in any given slot.

The management screen provides plenty of warning when the levels are getting low and it is not required to replace all four each time. Only the colour that is low.

Ink cartridges are easy to change

Regular maintenance

For any of us that have had experience running a siiver halide “wet” lab, it will probably be the daily/weekly/monthly maintenance regimes that flood back to our minds in a wave of nausea!

All that is truly a thing of the past and the regular maintenance of the DL450 is a breeze. Whats more, the printer is ready to print just 2mins after power-up!

Firstly, there is no calibration. Not when you you open a new batch of paper. Not when you change the chemicals... Not ever.

The only daily tasks are to remove the ink overspray pads and give them a wash and to remove paper dust from the transports using a blower or a brush.

Ink overspray pads in-situ (top lifted)

One of the ink overspray pads removed for washing

Less regularly is emptying the chaff bin. Chaff is the thin strips of paper that are left over when the lab cuts the trailing end off one print followed by the leading end of the next. These fall in to a *huge* bin stored beneath the ink cartridges. It is probably a good idea to make it a monthly or six-week task to check this because it takes so long to fill up you could easily forget about it altogether.

Just like the dry lab’s “wet” predecessors, there is a small device that prints on the back of each print. This has a typewriter-style fabric ink ribbon through which it prints lines of dot-matrix characters. This ribbon winds back and forth and eventually gets used up - signalled by the back-print getting faint. Renewing the ribbon is a simple matter of unclipping the printer module and changing the small cartridge.

The chaff bin (containing chaff)

Back-print unit removed

Copyright © 2010 - 2022 Mike Stroud