FUJIFILM DRY PHOTO LAB MS01

Management Software

Fujifilm’s range of minilabs (both wet and dry) and their wide format poster and canvas printers can all be controlled by a single, powerful management software application called... Management Software. Or MS01 for short. But, don’t let the daft name fool you, this is a comprehensive and feature-rich app that can be used in professional and supermarket labs alike.

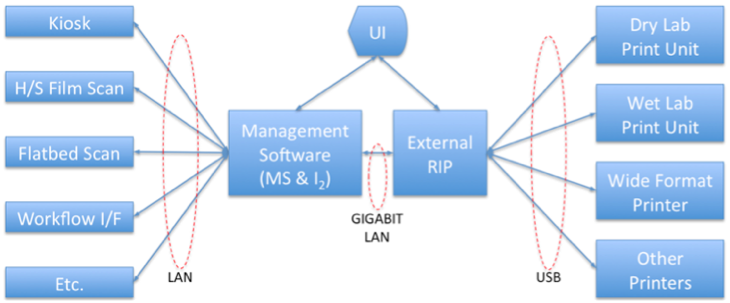

How it all hangs together

Components of a Fujifilm lab installation

The external rip runs on a separate PC mounted inside the DL450 or strapped (honest!!) to the outside of the DL400, DL410 & DL430. It is optional on the DL430 and DL600, but without it the DL430 has its maximum print size reduced to 10”x24” and the DL600 suffers from physical layout restrictions due to limitations in USB cable length. Also, it’s a must if you want to run more than one printer from a single MS01 job server.

Key features

Job Control

The key task of the MS application is to manage print jobs. These jobs could originate from kiosks, the internet and the lab itself using images from attached scanners, media readers, etc.

MS is based on the job control workflow that has evolved from class leading lab software used by Fuji over several years.

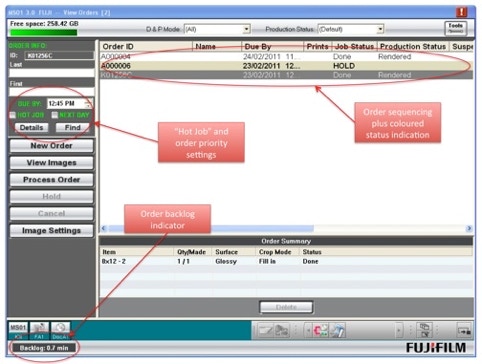

Jobs enter a queue via which they can be monitored continuously using a colour-based status indication. The software can be configured to automatically send jobs directly to the correct printer when the correct paper size and finish is detected or to pass every order into the preview and edit process. And everything in between.

Peak periods can be managed using a number of useful features such as:

Note - If any 3rd party order sources, such as non-Fuji kiosks or retailer’s own online photo site, are required as inputs to MS01 an additional module - MS13 - is required to provide the requisite connection capability.

The main order status screen from MS01 v3.0

Image Correction / Editing

Image Correction / Editing features

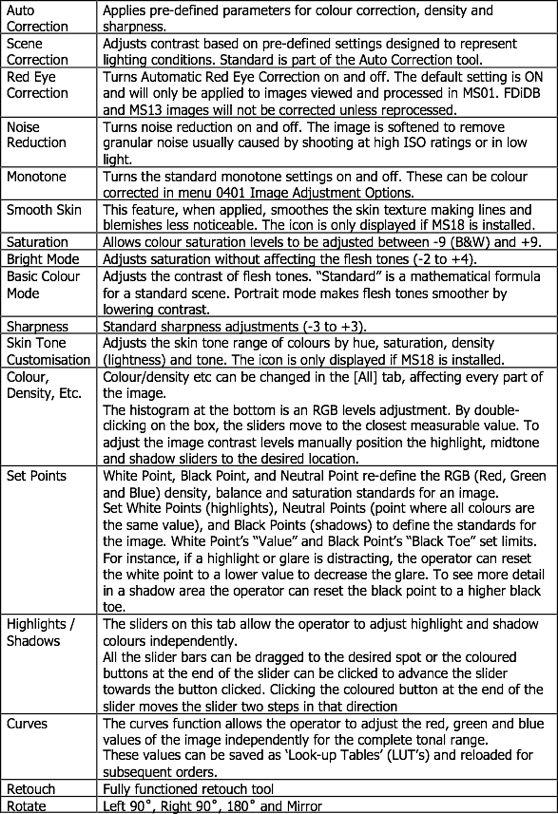

There are a few optional components which add features such as PhotoID, Skin Smoothing, Variety Print, etc., but in its default config, MS01 is pretty much fully loaded. The image correction / editing possibilities are significant.

Each function in the list of features on the right can be applied to a single image, a selection of images or an entire job. In addition the “standard” colour correction features found on the order preview screen can also be applied to virtually any combination of images. There is also a facility to save a set of corrections which can then be applied as needed.

Add to all this the ability to set fully automated correction on every order and it becomes clear just how powerful and flexible this application is. It is suitable for use in any environment from hard core professionals to supermarket 1hr photofinishers.

6-up job preview screen from MS01 v3.0

One of many image editing screens - Click to see more screen shots

Copyright © 2010 - 2022 Mike Stroud