FUJIFILM DRY PHOTO LAB DL600

Living with new technology

The DL600 is set to become Fujifilm’s flagship dry lab. This is a second generation printer that boasts a high resolution setting that will give photo stores the ability to offer premium services to their professional and pro-am customers. Add to that a light blue fifth ink to give those difficult sky tones real depth and you get a seriously high quality replacement for those exotic silver halide papers that we kept on hand for “special” jobs.

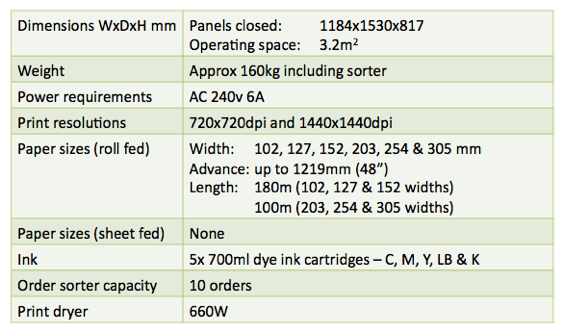

Basic specifications

Under the hood

Paper

Paper rolls are loaded directly on to adjustable spindles in the two paper chambers. It is necessary to swing the front chamber up out of the way in order to access the rear one.

The front chamber accepts paper from 102-203mm (4-8”) while the rear chamber can accept the full range of paper from 102-305mm (4-12”)

There is no cut sheet or duplex capability.

Paper storage is critical as inkjet paper is very sensitive to humidity and temperature, both high and low. All the time the paper is stored in its original sealed packaging between 15 & 30 Celsius it is fine. But, as soon as it is opened it has to be treated carefully. Once paper is loaded there is a humidity/temperature control device for each paper roll that ensures the paper stays in good condition. It pays to ensure that open packs of paper are used as soon as is practical.

Ink

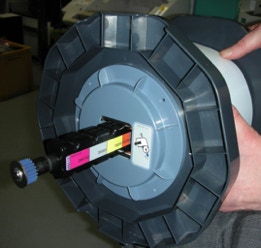

Just like its stablemates, the DL600 is an inkjet-based printer. The ink is supplied in decent-sized 700ml cartridges, and there are 5 of them. One each for the usual cyan, magenta, yellow and black plus an extra Light Blue ink, giving us CMYLBK. The light blue ink is specifically added to improve the banding effect seen in some scene types.

The ink cartridges are found behind a door in the right-hand front panel of the printer. Opening the door reveals the five cartridges which are not only clearly marked but they are also keyed to ensure it is not possible to insert the wrong colour in any given slot.

Front paper chamber

Access to the ink cartridges is via a door at the front.

Rear paper chamber

Ink cartridges and control panel

Adjustable spindle

Unlike any of the previous Fuji DL printers, the DL600 has a control panel which provides visual indication if an ink cartridge needs replenishment. The same panel also allows the user to indicate which paper finish is loaded in each of the paper chambers.

Regular maintenance

For any of us that have had experience running a silver halide “wet” lab, it will probably be the daily/weekly/monthly maintenance regimes that flood back to our minds in a wave of nausea!

All that is truly a thing of the past and the regular maintenance of the DL600 is even less than that of the DL450, if that’s possible! And, just like the DL450, it is ready to print just 2mins after power-up!

Control panel - warns of low ink & indicates which paper types are loaded

Like the other Fuji dry labs, there is no operator calibration. Ever. And on this machine, even head cleaning is automatic. Clever little sensors detect if one of the zillions of jets is blocked and just goes ahead and cleans it. Cool!

Daily - Unlike the DL450, the ink overspray pads are not removable so all that is needed each day is to rub them over with a cotton bud. At the same time brush (or blow) any paper dust from the paper transport mechanisms.

Less regularly - is emptying chaff, which are the thin strips of paper that are left over when the lab cuts the trailing end off one print followed by the leading end of the next. There is a large collection bin accessed via a port in the side of the lab. When the bin is removed access is gained to the backprinter unit. This has a typewriter-style fabric ink ribbon through which it prints lines of dot-matrix characters on the back of each print. This ribbon winds back and forth and eventually gets used up. The backprinter pulls out on a very complex, but convenient cantilever mechanism.

Lastly - and very rarely is the waste ink collector. This is where excess ink from overspray and head cleaning is managed. It takes the form of an absorbent pad which just needs a washout now and then.

Ink overspray pads

Backprinter extended for maintenance

Chaff bin & backprinter access instruction panel

Waste ink collector

Copyright © 2010 - 2022 Mike Stroud